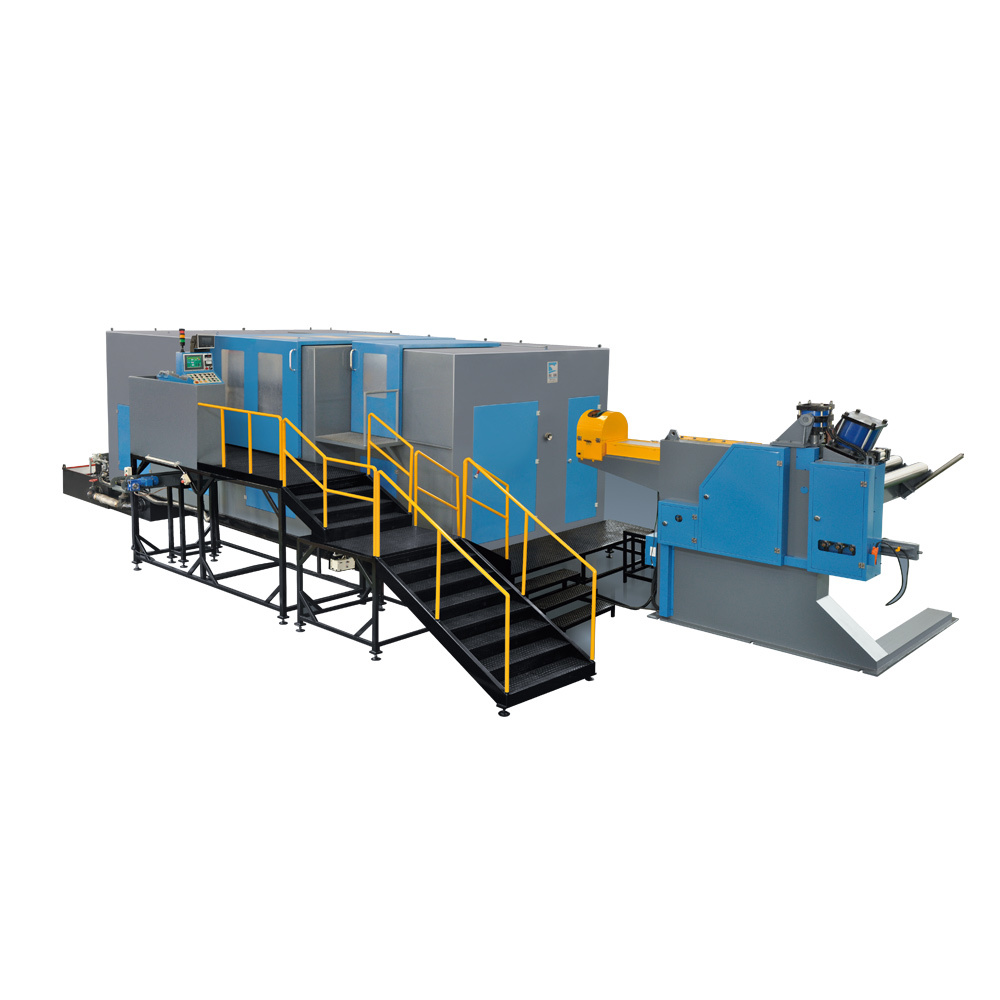

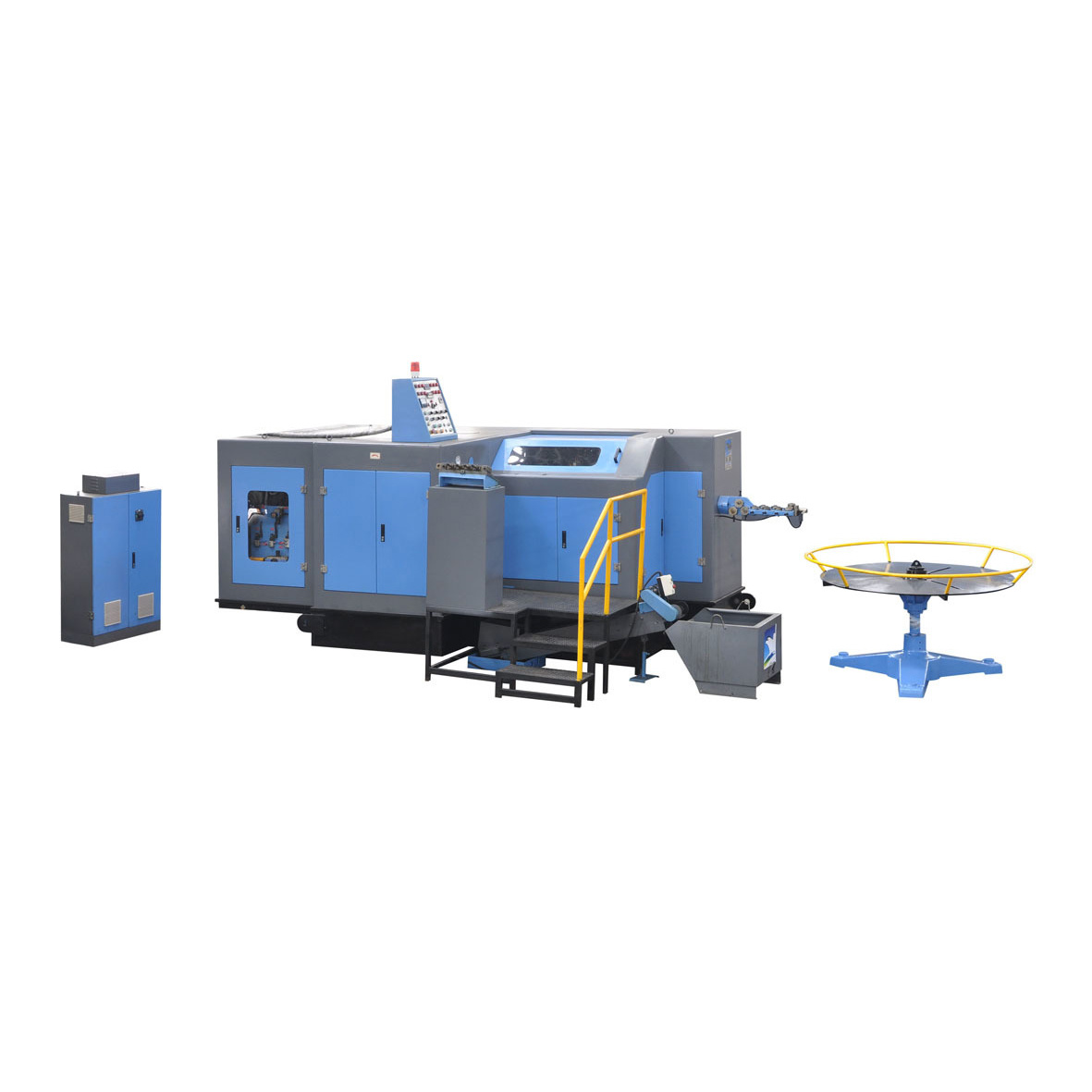

DBHP-8 high-precision high-speed intelligent cold heading forming machine

Cold heading is mainly used in the manufacture of bolts, nuts, nails, rivets and steel balls and other parts. The forging blank material can be copper, aluminum, carbon steel, alloy steel, stainless steel and titanium alloy, etc., and the material utilization rate can reach 80-90%. Cold heading is mostly carried out on a special cold heading machine, which is convenient for continuous, multi-station and automatic production. On the cold heading machine, the process of cutting, heading, accumulation, forming, chamfering, rolling, reducing diameter and trimming can be completed in sequence.

Key words:

Classification:

Key words: cold heading forming machine cold heading machine

E-mail:

Product Details

The three-die six-punch multi-stroke screw cold heading machine can make a wide range of products: ordinary screws, inner (outer) angle screws, hexagonal pad screws, multi-step screws and parts, super-large head short rod screws and parts, all-hollow pull nails, all-hollow ultra-long pull nails, semi-hollow rivets, cold forged special-shaped parts and other high-value-added products. The invention discloses a multi-station cold heading forming machine with turning function. The forming machine includes: a main mold is arranged on the side of a clamp table facing a clamp seat, and the main mold accommodates a workpiece to be processed: the clamp seat is pivotally connected with the clamp table through a connecting rod, the clamp seat is provided with at least one turning clamp, and each turning clamp corresponds to a transmission gear; the rotating shaft of the transmission gear is fixed on the clamp table: the flip gear, the clamp column, the clamp arm and the clamp piece, wherein the flip gear is fixedly connected with one end of the clamp column, and the flip gear meshes with the transmission gear; The rotation angle of the flip gear along the movement direction of the flip clamp is 90 degrees; The other end of the clamp column is provided with a clamp arm, and the corresponding end of the clamp arm and the main mold is provided with a clamp piece, which clamps the workpiece to be processed. Using the embodiment of the present invention, the workpiece to be processed can be turned 90 degrees.

Related Products

Message